Siyazi ukuba ukungunda kokutofa kubandakanya ukungunda okushukumayo kunye nokungunda okusisigxina.I-mold ephathekayo ifakwe kwi-template ehambayo yomshini wokubumba umjovo, kwaye i-mold esisigxina ifakwe kwi-template esisigxina yomshini wokubumba umjovo.Ngexesha lokubunjwa kwenaliti, i-mold ehambayo kunye ne-mold esisigxina ivaliwe ukwenza inkqubo yokungena kunye ne-cavity.Xa i-mold ivuliwe, i-mold ehambayo kunye ne-mold engatshintshiyo iyahlukana ukuze kukhutshwe imveliso yeplastiki.Ngoko ke ungakanani ulwazi malunga nokusetyenziswa kwale mveliso?Oku kulandelayo yintshayelelo emfutshane kumanyathelo okhuseleko phambi kokuba kuzanywe ukungunda inaliti.

Izilumkiso phambi kolingo lokungunda inaliti zichazwe ngolu hlobo lulandelayo:

1. Qonda ulwazi malunga nesitofu sokungunda: Kuyacetyiswa ukuba ufumane umzobo woyilo lwesitofu sokungunda, uhlalutye ngokweenkcukacha, kwaye emva koko uvumele injineli yokubumba inaliti ukuba ithathe inxaxheba kumsebenzi wovavanyo.

2. Okokuqala khangela intsebenziswano yomatshini kwi-workbench: nikela ingqalelo ukuba kukho imikrwelo, iindawo ezilahlekileyo kunye nezikhululekileyo, nokuba isenzo sokuslayida sobumba sinyani, kunye nombhobho wamanzi.

kunye nezifakelo zomoya zokuvuza, kwaye ukuba ukuvuleka kwesitofu sokungunda kusisithintelo, kufuneka kumakishwe.Ukuba ezi zenzo zingentla zingenziwa phambi kokuxhoma ukungunda kwesitofu, iingxaki ezifumaneka xa kuxhonywa ukungunda kwesitofu zinokuphetshwa, kwaye ke ukuchitha iiyure zomntu xa kususwa ukungunda inaliti kunokuphetshwa.

3. Xa kugqitywe ukuba ukunyakaza kwenxalenye nganye ye-injection mold kugqityiwe, kuyimfuneko ukukhetha umatshini wokubumba umjovo ofanelekileyo.

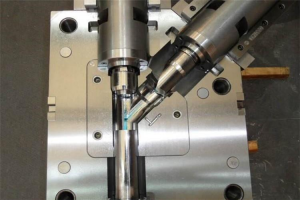

4. Xa uxhoma isikhunta, kufuneka kuqatshelwe ukuba ngaphambi kokuba uvale zonke izibonda kunye nokuvula isikhunta, ungasusi isitshixo kwaye usithintele ukuba singawi ngenxa yeentambo ezivulekileyo okanye eziphukileyo.Emva kokuba i-mold ifakwe, isenzo somatshini wecandelo ngalinye lokubumba kufuneka lihlolwe ngononophelo, njengokuba ipleyiti yesilayidi kunye ne-thimble isebenza ngokuchanekileyo kwaye ingaba i-nozzle ihambelana ne-port yokutya.

5. Xa uvala i-mold, uxinzelelo lwe-clamping kufuneka luncitshiswe.Ngethuba lemisebenzi ye-clamping ye-manual kunye ne-low-speed, ingqwalasela kufuneka ihlawulwe ukujonga kunye nokuphulaphula nayiphi na intshukumo kunye nezandi ezingaqhelekanga.Inkqubo yokuphakamisa ukungunda eneneni ilula kakhulu.Into ephambili ekufuneka uyiqaphele kukuba isango lokubumba kunye neziko le-nozzle linzima kakhulu.Ngokuqhelekileyo, iziko linokulungiswa kunye nomtya wokuvavanya.

6. Khetha umatshini ofanelekileyo wokulawula ubushushu bomngundo ukwandisa ubushushu bokubumba kwiqondo lokushisa elifunwayo ngexesha lenkqubo yokuvelisa.Emva kokuba ukushisa kwesikhunta kunyukile, khangela kwakhona ukuhamba kwenxalenye nganye.Ekubeni intsimbi inokubangela ukufa ngenxa yokwandiswa kwe-thermal, kufuneka kuthathelwe ingqalelo ukuba inxalenye nganye ityibilike ukuthintela ukuncokola.

Ixesha lokuposa: Jan-20-2022